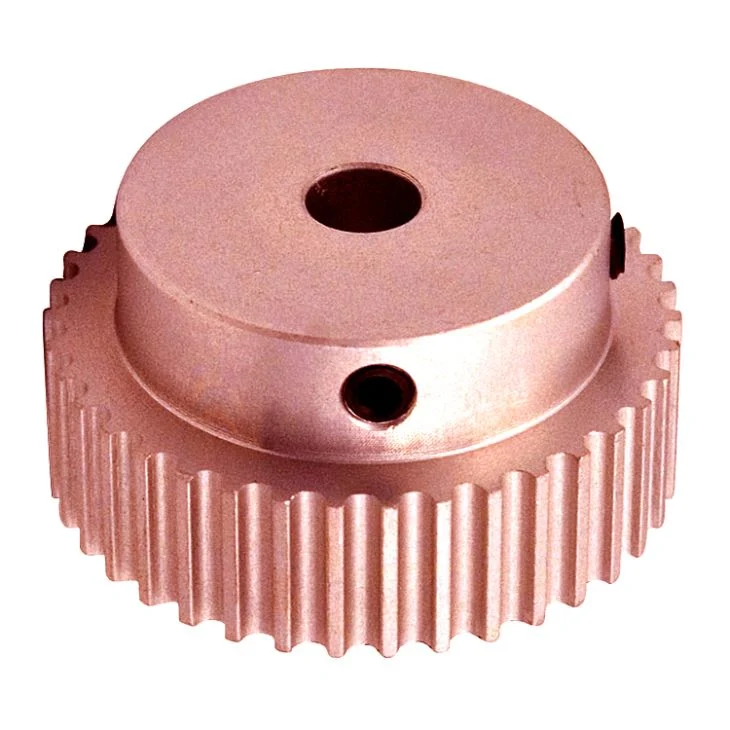

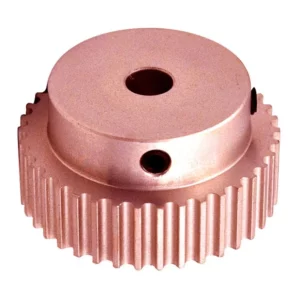

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer

As one of the compound pulley manufacturers, suppliers, and exporters of mechanical products, We offer compound pulley and many other products.

Please get in touch with us for details.

mailto:Mail:[email protected]

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer

Introduction

The Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer is a versatile and essential component used in various industries. It is designed to efficiently transmit power and change the direction of a force. This compound pulley offers exceptional adjustability, flexibility, mechanical advantage, efficiency, and versatility, making it a valuable tool in many applications.

Key Features and Advantages

- Adjustability: The compound pulley allows for precise adjustment, ensuring optimal performance in different situations.

- Flexibility: With its versatile design, the compound pulley can accommodate various belt types and sizes, offering flexibility in system configuration.

- Mechanical Advantage: The compound pulley provides a mechanical advantage, enabling the user to lift heavy loads with less effort.

- Improved Efficiency: By effectively distributing the load and minimizing friction, the compound pulley enhances overall system efficiency.

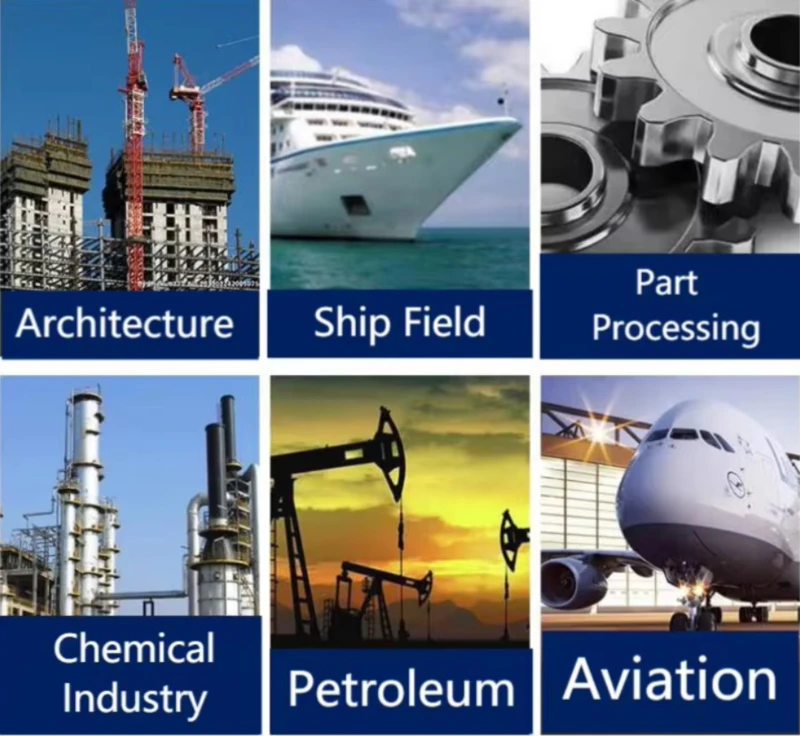

- Wide Range of Applications: From lifting equipment to industrial machinery, the compound pulley finds applications in industries such as construction, manufacturing, and logistics.

- Increased Height and Range: The compound pulley allows for greater lifting height and range, expanding the capabilities of the lifting system.

Working Principle

The compound pulley operates on the principle of distributing the force applied to the system across multiple pulleys. By having multiple grooved wheels in the pulley system, the compound pulley effectively reduces the force required to lift heavy loads. As the rope or belt is threaded through the pulleys, the load is divided and shared between them, resulting in a mechanical advantage that allows for easier lifting and movement.

Specific Applications

The Compound Pulley is widely used in various industries and applications. Its versatility and mechanical advantages make it suitable for tasks such as:

- Lifting heavy objects in construction sites

- Supporting overhead cranes in manufacturing facilities

- Aiding in the operation of elevators

- Assisting in the movement of stage equipment during live performances

Definition of Compound Pulley

The compound pulley is a type of pulley system that consists of multiple pulleys arranged in a specific configuration. Unlike a single pulley, which only changes the direction of a force, the compound pulley provides a mechanical advantage by distributing the load over multiple pulleys. This design allows for easier lifting of heavy objects and reduces the amount of force required.

Differences between Compound Pulley and Single Pulley

The compound pulley differs from a single pulley in several ways:

- A single pulley has only one grooved wheel, while a compound pulley has multiple grooved wheels.

- A single pulley changes the direction of a force, while a compound pulley provides a mechanical advantage by distributing the load.

- A single pulley requires the same amount of force as the load being lifted, while a compound pulley reduces the required force by sharing the load across multiple pulleys.

Basic Structure of Compound Pulley

The compound pulley consists of the following essential components:

- Pulley Wheels: These grooved wheels provide traction for the rope or belt.

- Shafts: The pulley wheels are mounted on shafts, allowing them to rotate.

- Frame or Housing: The frame or housing supports and encloses the pulley wheels and shafts, ensuring stability and proper alignment.

- Rope or Belt: The rope or belt is threaded through the grooves of the pulley wheels, transmitting force and enabling the lifting or movement of loads.

Common Components of Compound Pulley

The compound pulley commonly consists of the following components:

- Pulley Wheels: These wheels provide the necessary traction and support for the rope or belt.

- Shafts: The pulley wheels are mounted on shafts that allow them to rotate smoothly.

- Bearings: Bearings are used to reduce friction between the rotating shafts and the frame or housing.

- Frame or Housing: The frame or housing holds the pulley system together, providing stability and support.

- Rope or Belt: The rope or belt is threaded through the pulley wheels, transmitting force and enabling the lifting or movement of loads.

Changing Force Magnitude and Direction

The compound pulley can change the magnitude and direction of a force by utilizing the mechanical advantage provided by multiple pulleys. By increasing the number of pulleys in the system, the force required to lift a load is reduced. Additionally, the arrangement of the pulleys can be adjusted to change the direction of the force, allowing for lifting or movement in different directions.

Common Industries Using Compound Pulley

The compound pulley is commonly used in various industries, including:

- Construction: The compound pulley is utilized in lifting heavy construction materials and equipment.

- Manufacturing: It plays a crucial role in supporting overhead cranes and facilitating material handling processes in manufacturing facilities.

- Logistics: The compound pulley is used in the movement and lifting of goods in warehouses and distribution centers.

- Theater and Entertainment: It assists in the smooth operation of stage equipment and flying systems during performances.

Materials and Manufacturing Processes

The compound pulley is commonly manufactured using durable materials such as:

- Cast Iron: Known for its strength and durability, cast iron is often used for the pulley wheels and frame.

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for pulley components that require reduced weight.

- Plastic: Certain pulley components, such as housing or covers, may be made from high-strength plastic materials.

The manufacturing processes involved in producing compound pulleys include casting, machining, and assembly. Advanced CNC (Computer Numerical Control) machines are employed to ensure precision and consistency in the production of pulley components.

Common Failures of Compound Pulley

Despite their durability, compound pulleys may experience certain common failures, including:

- Wear and Tear: Over time, the pulley wheels and bearings may wear out, leading to decreased performance and potential malfunctions.

- Misalignment: Improper installation or usage can cause misalignment between the pulley components, resulting in increased friction and reduced efficiency.

- Belt Slippage: If the belt tension is not properly maintained, slippage can occur, reducing the overall effectiveness of the pulley system.

Daily Maintenance for Optimal Performance

To ensure the proper functioning of the compound pulley and extend its lifespan, regular maintenance is essential. The following practices are recommended:

- Inspect the pulley system regularly for signs of wear, damage, or misalignment.

- Keep the pulley wheels clean and free from debris or buildup that could interfere with their rotation.

- Maintain proper belt tension to prevent slippage and optimize performance.

- Lubricate the bearings and moving parts as recommended by the manufacturer to minimize friction and prolong their lifespan.

Trends in Compound Pulley Technology

The development of compound pulley technology is driven by several key trends:

- Advanced Materials: The use of lightweight and high-strength materials such as carbon fiber composites is increasing, resulting in pulleys with improved performance and reduced weight.

- Enhanced Design and Efficiency: Continuous improvements in pulley design and engineering are leading to more efficient systems with higher load capacities and lower friction.

- Integration with Automation: Compound pulleys are being integrated into automated systems, enhancing productivity and reducing the need for manual operation.

Company and Product Promotion

Our company is a leading player in the pulley market in China. We offer a wide range of high-quality products, including Compound Pulleys, Pulley Pullers, Belt Pulleys, Tensioner Pulleys, Gear Pulleys, Spring Pulleys, Lifting Pulleys, Belt Idler Pulleys, Timing Pulleys, V Pulleys, Plastic Pulleys, and more. With our state-of-the-art CNC production equipment and automated assembly systems, we ensure the precision and reliability of our products.

We take pride in providing excellent products at competitive prices, accompanied by attentive customer service. Whether you require standard products or customized solutions, our team is dedicated to meeting your specific requirements. Join our growing list of satisfied customers and experience the quality and performance of our pulley products.

Welcome! Customers are welcome to provide their own designs and samples for custom pulley solutions. Contact us today to discuss your needs and benefit from our expertise and comprehensive range of pulley products.

Related Products

-

Heavy Duty Poly V Sheave Multi-Ribbed Compound Belt Wheel Cast Iron Drive Grooved Tension Bushing Pulley for Electric Motor

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer

-

Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension