Compound Pulley

HIGH QUALITY PRECISE MANUFACTURER &SUPPLIER

Leading Innovator in Compound Pulley Solutions

We are a leading manufacturer and distributor specializing in the production of compound pulleys. Over the years, we have grown into a large-scale enterprise with advanced manufacturing facilities and a dedicated team of engineers and technicians. Our commitment to quality and innovation has positioned us as a trusted name in the industry.

Our compound pulleys are renowned for their unique design and exceptional performance. Combining the advantages of fixed and movable pulleys, our products offer significant mechanical advantages, making them highly efficient in reducing the effort needed to lift heavy loads. This flexibility allows for adjustable configurations to suit various needs, making our compound pulleys ideal for applications in construction, logistics, marine operations, and industrial manufacturing.

We pride ourselves on our expertise in compound pulleys. Our products are developed using cutting-edge technology and adhere to the highest standards of quality and durability, earning us a solid reputation and a loyal customer base worldwide.

We are dedicated to providing outstanding customer service, from initial consultation through to after-sales support. Our team is always ready to assist with technical guidance and maintenance advice, ensuring our clients get the most out of our products. Continuous innovation drives our business, and we are constantly developing new solutions to meet the evolving demands of the industry.

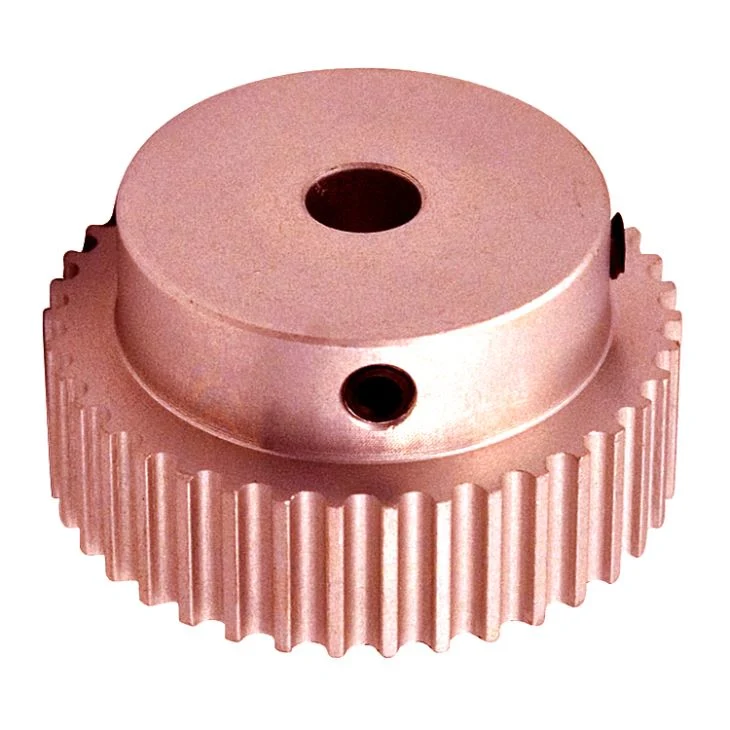

Compound pulley for sale

-

Heavy Duty Poly V Sheave Multi-Ribbed Compound Belt Wheel Cast Iron Drive Grooved Tension Bushing Pulley for Electric Motor

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer

-

Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension

-

Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension

-

V Belt Pulley Taper Lock Adjustable Pulleys for Taper Bushes with Solid Hub Grooved Double 6 Inch Step Variable Speed Variable Congress Small Aluminum Sheave

What is Compound Pulley?

A compound pulley, also known as a combination pulley or a block and tackle system, is a mechanical device that utilizes multiple pulleys and ropes or cables to increase the mechanical advantage of lifting or pulling a load. It is a more complex and efficient version of a simple pulley system. A compound pulley system consists of multiple pulleys, usually arranged in a block and tackle configuration. The ropes or cables are threaded through the pulleys in a specific manner to provide a greater mechanical advantage. This means that the force required to lift or pull a load is reduced compared to using a simple pulley or doing the work manually.

Features of Compound Pulley

Mechanical Advantage

The primary feature of a compound pulley is its ability to provide significant mechanical advantage. By combining multiple pulleys, the system reduces the amount of force needed to lift heavy loads, making tasks easier and more efficient.

Combination of Fixed and Movable Pulleys

A compound pulley system integrates both fixed pulleys, which change the direction of the force, and movable pulleys, which reduce the force needed. This combination allows for greater flexibility and efficiency in lifting operations.

Direction Change

Fixed pulleys in the system allow for the direction of the applied force to be changed, making it more convenient to lift loads in different directions and reducing the physical strain on the operator.

Adjustability

The arrangement of pulleys in a compound system can be adjusted to achieve different mechanical advantages, making it versatile for various lifting requirements and applications.

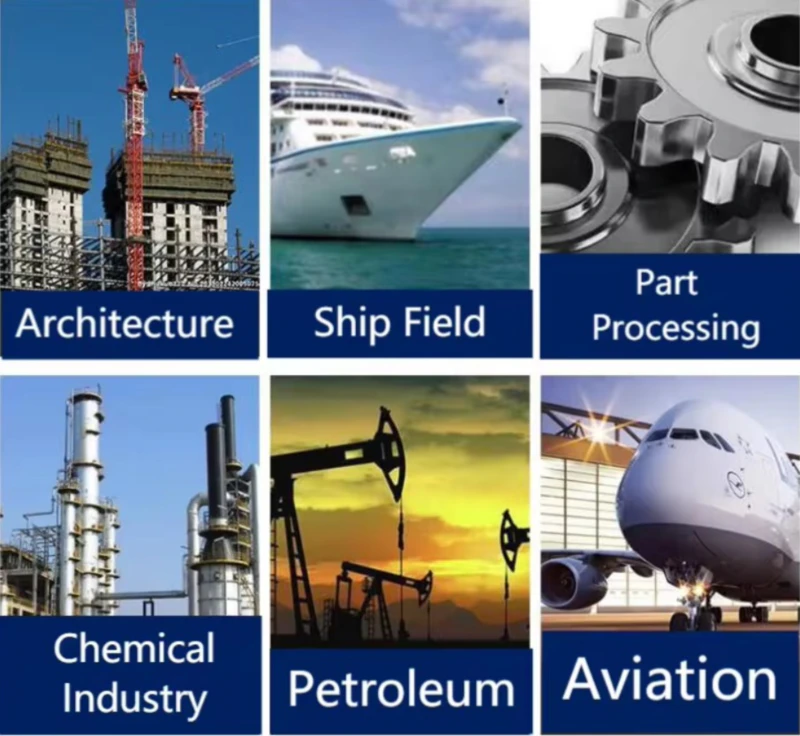

Common industries for compound pulley

Construction

Applications: Lifting heavy building materials, moving construction equipment, positioning structural elements.

Benefits: Reduces the physical strain on workers, increases efficiency, and enhances safety on construction sites.

Manufacturing and Industrial

Applications: Handling heavy machinery, moving large components, assisting in assembly lines.

Benefits: Improves workflow efficiency, reduces manual labor, and minimizes the risk of injury.

Logistics and Warehousing

Applications: Loading and unloading heavy goods, moving large crates and pallets, organizing warehouse storage.

Benefits: Enhances material handling efficiency, reduces time and effort, and optimizes space utilization.

Marine and Shipping

Applications: Loading and unloading cargo, moving heavy ship components, handling fishing nets and gear.

Benefits: Facilitates safe and efficient cargo handling, reduces manpower requirements, and improves operational efficiency.

Mining

Applications: Lifting and transporting heavy mining equipment, moving extracted materials, assisting in underground operations.

Benefits: Enhances productivity, reduces physical labor, and ensures safer working conditions in challenging environments.

Rescue and Emergency Services

Applications: Lifting debris during rescue operations, moving injured persons, accessing difficult-to-reach areas.

Benefits: Provides quick and safe lifting solutions, reduces rescue operation time, and enhances overall safety.

Materials and processes used in the manufacture of compound pulley

Materials

Metal materials:

Steel: Commonly used to make pulley wheels and shafts. Due to its high strength and durability, it is suitable for heavy-load applications.

Aluminum: Lightweight and corrosion-resistant, suitable for occasions where the overall weight of the equipment needs to be reduced.

Stainless steel: Has excellent corrosion resistance and is suitable for corrosive environments such as marine and chemical industries.

Alloy materials:

Aluminum alloy: Combines the lightweight characteristics of aluminum with the strength of other metals and is often used in applications that require high strength and lightness.

Magnesium alloy: Lighter than aluminum alloy, suitable for high-performance fields that are sensitive to weight.

Polymer materials:

Nylon: It has good wear resistance and self-lubricating properties and is often used in the wheel part of the pulley.

Polypropylene: Lightweight and chemically resistant, suitable for medium-load applications.

Manufacturing process

Metal casting:

Sand casting: Suitable for the production of large-sized and complex-shaped metal pulleys, and metal parts are manufactured through sand molds.

Die casting: Used for the production of high-precision, small metal parts suitable for mass production.

Metal Processing:

CNC Turning: Used to process the shaft and other round parts of the pulley, and CNC machines precisely cut the metal.

CNC Milling: Used to process the wheels and grooves of the pulley, and CNC machines precisely cut the metal.

Metal Forming:

Stamping: Suitable for mass production of metal pulley parts, the metal sheet is stamped and formed by a die.

Forging: Used to manufacture high-strength pulleys, and the internal structural strength of the metal is improved by the forging process.

Welding and Assembly:

Welding: Used for the connection and reinforcement of pulley components, often using MIG, TIG, or resistance welding processes.

Assembly: The final assembly of the pulley system and the performance and reliability of the pulley are ensured through precision assembly and testing.

Polymer Molding:

Injection Molding: Used to produce polymer pulley parts by injecting molten polymer into a mold.

Extrusion Molding: Used to manufacture long polymer parts, and the polymer material is extruded and formed by an extruder.

Surface treatment

Electroplating: Plating a layer of metal on the surface of the pulley, such as zinc plating or nickel plating, to improve its corrosion resistance.

Spraying: Spraying a protective coating on the surface of the pulley, such as spray painting or powder spraying, to improve its wear resistance and aesthetics.

Anodizing: Used for aluminum pulleys, an oxide film is formed on the surface through an electrochemical process to improve its corrosion resistance.

Blog

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality compound pulley. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your compound pulley is in optimal condition for a more extended period.

5. Rich product range: Our company provides a variety of compound pulley shafts to meet different applications and requirements. We can provide you with the right product.