Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension

As one of the compound pulley manufacturers, suppliers, and exporters of mechanical products, We offer compound pulley and many other products.

Please get in touch with us for details.

mailto:Mail:[email protected]

Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension

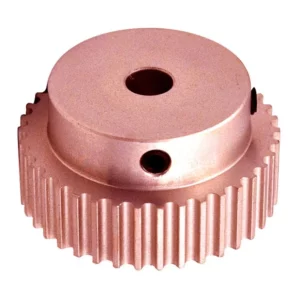

A compound pulley is a versatile and efficient tool used in various industries. It is designed to increase mechanical advantage and improve efficiency in lifting heavy loads. Unlike a single pulley, a compound pulley consists of multiple pulleys working together to distribute the load and reduce the effort required.

Definition and Differences from a Single Pulley

A compound pulley is a system of pulleys that work together to create a mechanical advantage. Unlike a single pulley, which only changes the direction of the force, a compound pulley also allows for the adjustment of force magnitude.

Basic Working Principle

The basic working principle of a compound pulley is the concept of mechanical advantage. By distributing the load across multiple pulleys, the force required to lift the load is reduced. As the rope is pulled, tension is evenly distributed among the pulleys, allowing for easier lifting of heavy objects.

Basic Structure

A compound pulley system consists of multiple pulleys mounted on a common frame or axle. The pulleys are arranged in such a way that the rope passes through them, creating a system of ropes and pulleys that work together to lift heavy loads.

Common Components

Some common components of a compound pulley system include the pulley wheels, rope or cable, frame or axle, and any additional support structures or mechanisms required for mounting and operation.

Adjusting Force Magnitude and Direction

A compound pulley system allows for the adjustment of force magnitude by varying the number of pulleys used. By increasing the number of pulleys, the mechanical advantage and force reduction are increased, making it easier to lift heavy loads. Additionally, the direction of the force can be changed by adjusting the position of the rope or cable.

Common Industries

The compound pulley system finds applications in various industries, including construction, manufacturing, logistics, and transportation. It is widely used in tasks that involve heavy lifting, such as construction site operations, cargo handling, and material transportation.

Materials and Manufacturing

Compound pulleys are typically made from durable materials such as steel, aluminum, or plastic, depending on the specific application requirements. The manufacturing process involves precision engineering and machining techniques to ensure the pulleys' smooth operation and long-lasting performance.

Common Issues and Maintenance

Common issues that may arise with compound pulleys include wear and tear of the pulley wheels, fraying or weakening of the rope or cable, and misalignment of the pulley system. To ensure the proper functioning of the compound pulley, regular inspection, lubrication, and replacement of worn-out components are recommended.

Technological Advancements and Impact

The development of compound pulley technology is driven by the demand for more efficient and reliable lifting solutions. Advancements in materials, such as the use of lightweight and high-strength alloys, enhance the pulley's performance and durability. Additionally, the integration of smart technologies, such as sensors and automation, improves the precision and safety of compound pulley systems.

Company and Product Promotion

We are a leading company in the pulley market in China, offering a wide range of high-quality products. Our product lineup includes compound pulleys, pulley pullers, belt pulleys, tensioner pulleys, gear pulleys, spring pulleys, lifting pulleys, belt idler pulleys, timing pulleys, V pulleys, belt and pulley systems, and plastic pulleys. With our state-of-the-art fully automated CNC production equipment and assembly systems, we ensure the highest level of precision and quality in our products.

At our company, we pride ourselves on delivering exceptional products, competitive prices, and excellent customer service. We welcome customization requests and are committed to meeting our customers' specific needs. Please feel free to contact us with any inquiries or to place an order.

Thank you for considering our company and products. We look forward to serving you!

Related Products

-

Heavy Duty Poly V Sheave Multi-Ribbed Compound Belt Wheel Cast Iron Drive Grooved Tension Bushing Pulley for Electric Motor

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley

-

Pulley Wheel Flat Belt Electric Motor Poly V Sheave Multi-Ribbed Rope Cable Plastic Aluminum Sheave Compound Cast Iron Heavy Duty Tension Pulley Spacer

-

Pulley Wheel Flat Belt Gearbox Electric Motor Pulleys Poly V Sheave Multi-Ribbed Rope Cable Winch Plastic Small Aluminum Compound Cast Iron Heavy Duty Tension